7.1. Non-Towing Services

BEFORE JACKING THE VEHICLE

7.1 BEFORE JACKING THE VEHICLE

Ensuring ground stability and appropriate conditions are crucial when jacking a vehicle to perform maintenance or other tasks safely. Failing to do so can lead to accidents, injuries, or damage to the vehicle. Here are steps to ensure the ground is stable and suitable for jacking a vehicle:

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Choose the Right Location

- Select a flat, level, and solid surface for jacking the vehicle. Ideally, use a concrete or asphalt surface.

- Avoid soft or uneven ground like grass, dirt, gravel, or sand, as it can shift and cause the vehicle to become unstable.

Inspect the Ground

- Check the selected area for any cracks, holes, or unevenness that could affect stability.

- Remove any debris, rocks, or objects from the area where the vehicle will be jacked.

Use Jack Stands

- Always use jack stands in addition to the hydraulic or scissor jack when lifting a vehicle. Jack stands provide added stability and safety.

- Ensure that the jack stands have a wide, flat base and are placed on a stable surface.

Secure the Vehicle

- Before jacking, make sure the vehicle is in “Park” or gear (for manual transmissions) and the parking brake is engaged.

- If the vehicle has a manual transmission, you may also consider chocking the wheels with wheel chocks for extra security.

-

Check the Jack's Condition

- Inspect the jack for any signs of damage or wear. Make sure it’s functioning correctly and has the weight capacity necessary for the vehicle.

-

Position the Jack Properly

- Place the jack at the manufacturer-recommended jacking points, typically indicated in the vehicle’s owner’s manual. These points are designed to support the weight of the vehicle safely.

-

Lift Slowly and Steadily

- When using a hydraulic jack, pump the handle slowly and steadily to raise the vehicle. Avoid sudden jerking motions.

- Continuously monitor the stability of the vehicle as it’s being lifted.

-

Use Jack Stand Height

- Adjust the height of the jack stands to match the lifted height of the vehicle.

- Lower the vehicle onto the jack stands gently.

-

Verify Stability

- After lowering the vehicle onto the jack stands, give it a gentle shake to ensure it’s stable and secure on the stands.

- Double-check that the vehicle is not wobbling or tilting.

-

Work Safely

- When working under the vehicle, use proper safety equipment, such as safety glasses and gloves.

- Avoid placing any body parts under the vehicle while it’s supported only by the jack.

-

Regularly Check Stability

- Periodically recheck the stability and condition of the jack stands and the vehicle while you’re working underneath it.

-

Lower the Vehicle Carefully

- When you’re done working under the vehicle, raise it slightly with the jack and remove the jack stands.

- Lower the vehicle slowly and steadily back to the ground.

-

By following these steps and paying close attention to ground stability and proper jacking procedures, you can minimize the risk of accidents and ensure your safety when working on or under a vehicle. Always prioritize safety and take precautions to prevent any potential hazards.

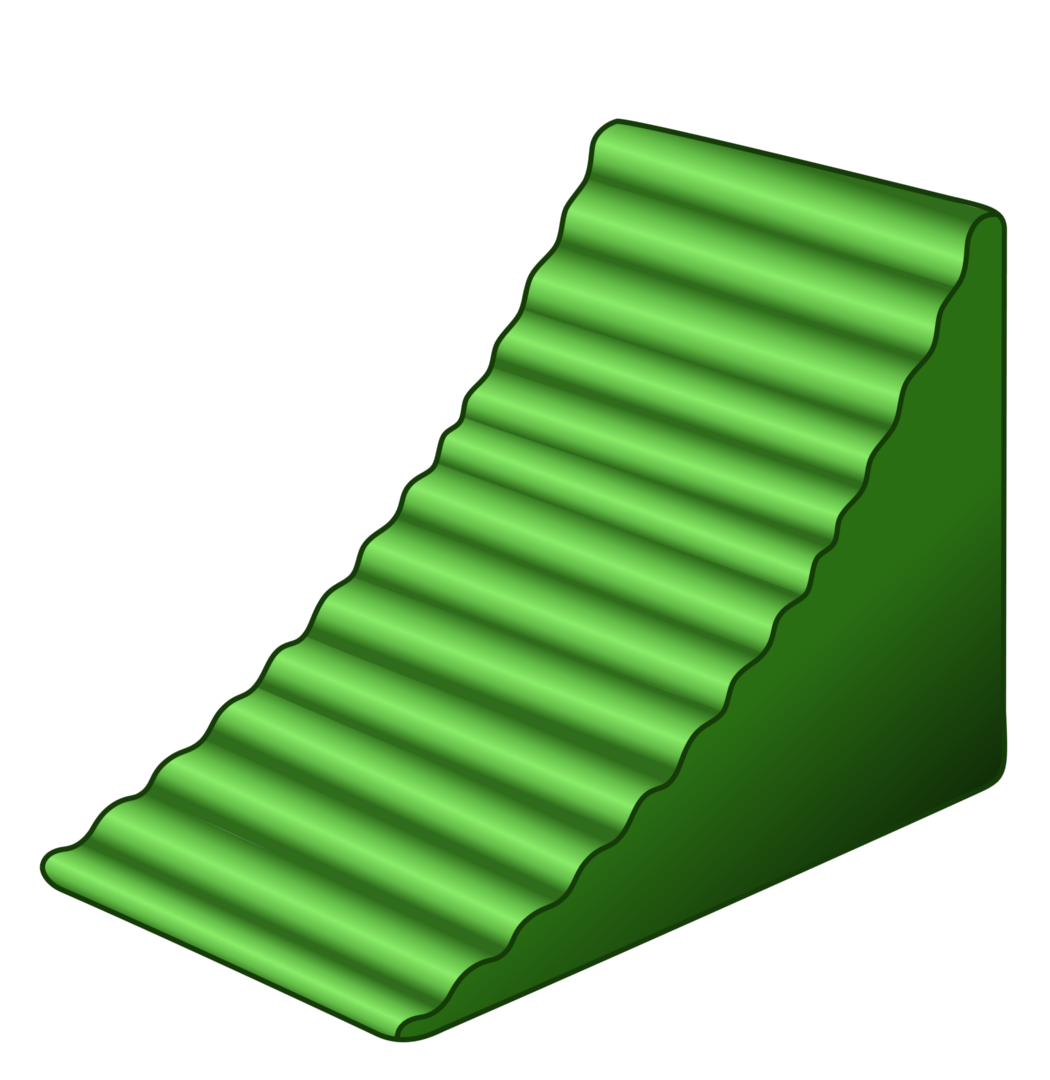

WHEEL CHOCKS

7.1 WHEEL CHOCKS

Securing a disabled vehicle using wheel chocks is essential to prevent it from rolling while performing maintenance or recovery operations. Wheel chocks are wedge-shaped devices placed in front of and behind the vehicle’s wheels to prevent it from moving. Here’s how to ensure a disabled vehicle is properly secured with wheel chocks:

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Select Appropriate Wheel Chocks

Choose wheel chocks that are sturdy and appropriate for the size and weight of the vehicle. Chocks should be designed to withstand the vehicle’s weight and be made of durable materials.

Park the Vehicle on a Flat Surface

Ensure that the vehicle is parked on a level and stable surface. If the ground is uneven or sloped, attempt to find a more suitable location.

Engage the Parking Brake

- If the vehicle has an automatic transmission, put it in “Park.” For manual transmissions, place the vehicle in gear.

- Engage the parking brake firmly to prevent the vehicle from moving.

Turn Off the Engine

Ensure the vehicle’s engine is turned off to prevent accidental movement when working on it.

Identify the Wheel Placement

Determine whether you need to chock the front or rear wheels, or both, depending on the maintenance or recovery task.

Position the Chocks

- Place one wheel chock in front of the wheel and the other behind it. For rear-wheel drive vehicles, chock the front wheels, and for front-wheel drive vehicles, chock the rear wheels.

- Position the chocks as close to the tires as possible, so there is minimal space between the chock and the tire.

Angle the Chocks

Angle the chocks so that they form a triangle with the tire. This provides better stability as the vehicle tries to move forward or backward.

Ensure a Snug Fit

Push the chocks firmly against the tires, making sure they are snugly in place. You should feel some resistance when positioning them.

Test Stability

Gently try to move the vehicle to ensure it remains stable. The wheel chocks should prevent any significant movement of the vehicle.

Double-Check All Four Wheels

If your vehicle has all four wheels on the ground, repeat the chocking process for the remaining wheels.

Proceed with Work

With the vehicle securely chocked, you can safely perform maintenance or recovery operations, such as changing a tire, working underneath the vehicle, or attaching towing equipment.

Remove Chocks After Work

Once you’ve completed your tasks, remove the wheel chocks before attempting to drive the vehicle. Store the chocks in a secure location for future use.

Wheel chocks are a vital safety measure to prevent accidents caused by unintended vehicle movement. Always use them when working on a disabled vehicle or any situation where vehicle stability is a concern. Properly securing the vehicle with wheel chocks can help ensure your safety and the safety of those around you.

THE SAFEST WORKING ANGLE

7.1 THE SAFEST WORKING ANGLE

The safest working angle to service a disabled vehicle depends on the specific situation and the type of service being performed. However, there are some general guidelines to consider when determining the safest working angle:

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Flat and Level Surface

Whenever possible, choose a flat and level surface to work on the disabled vehicle. This provides the most stability and minimizes the risk of the vehicle rolling or shifting unexpectedly.

Safety Zones

If the disabled vehicle is on a road or in a location with traffic, prioritize the safety of you and other road users. Position the vehicle as far off the road as possible within a designated safety zone, such as the shoulder or an emergency lane.

Parking Brake and Wheel Chocks

Engage the parking brake on the disabled vehicle and use wheel chocks to prevent it from rolling. This is crucial for safety when working on the vehicle, especially if it’s on an incline.

Position for Access

Consider the specific service you need to perform. Position the vehicle in a way that provides easy and safe access to the area you’ll be working on. For example, if changing a tire, position the disabled vehicle with the flat tire closest to the curb or off the road.

Visibility and Traffic Flow

Ensure that your working angle allows for good visibility to oncoming traffic and that it does not obstruct the flow of traffic. If you need to block a lane, use warning devices such as hazard lights, reflective triangles, or cones to alert other drivers.

Emergency Lights and Reflectors

Use the vehicle’s emergency lights and reflective markers or triangles to make the disabled vehicle more visible to others, especially in low-light conditions or inclement weather.

Consider the Weight Distribution

If you’re towing or recovering the disabled vehicle, ensure that the towing equipment is properly positioned and that the weight distribution is balanced to prevent tipping or instability.

Work on a Stable Surface

If you need to work underneath the vehicle (e.g., for maintenance or repairs), use jack stands on a level surface. Do not rely solely on a hydraulic or scissor jack to support the vehicle.

Vehicle Safety Features

Understand the safety features of the vehicle, especially if it’s a newer model with advanced driver assistance systems (ADAS). Be cautious when working around sensors, cameras, or other components that may be sensitive to changes in angle or positioning.

Emergency Response Plan

Always have an emergency response plan in place, including access to communication devices like a cellphone or two-way radio, in case you need assistance while servicing the disabled vehicle.

Ultimately, the safest working angle for servicing a disabled vehicle prioritizes the safety of both the service provider and others on the road. It may require adjusting the vehicle’s positioning, using safety equipment, and following proper procedures to minimize risks and ensure a safe working environment.