6.7. Hostile Terrain & Resistance Factors

ASSESSING GROUND STABILITY, OBSTACLES, EXTRACTION PATH, & ANCHOR REQUIREMENTS

6.7. ASSESSING GROUND STABILITY, OBSTACLES, EXTRACTION PATH, & ANCHOR REQUIREMENTS

Preparing to tow or recover a casualty from hostile terrain involves a systematic assessment of ground stability, obstacles, extrication path, and anchor requirements to ensure a safe and effective operation. Here is a step-by-step process for this assessment:

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Safety Briefing and Team Coordination

- Gather the recovery team and conduct a safety briefing to ensure everyone understands their roles and responsibilities.

- Establish clear communication protocols and signals.

Assessment of Ground Stability

- Evaluate the terrain’s stability and ground conditions.

- Consider factors such as soil type, slope, weather conditions (rain can make terrain unstable), and any signs of instability (cracks, loose rocks, etc.).

- Determine if the ground can support the weight of the recovery vehicle and the casualty.

Obstacle Assessment

- Identify obstacles in the recovery path such as rocks, trees, or other terrain features that may impede progress.

- Assess the size, shape, and stability of these obstacles.

- Plan for their avoidance or removal, if necessary, using appropriate tools and equipment.

Extrication Path Planning

- Determine the best route to reach the casualty, considering ground stability and obstacles.

- Prioritize safety by avoiding steep inclines, unstable terrain, or areas prone to avalanches or landslides.

- Mark the extrication path clearly, using markers or guides if possible.

Anchor Requirements

- Assess the need for anchors to secure the recovery vehicle and prevent it from sliding or tipping over during the operation.

- Identify natural anchors like sturdy trees or rocks, or consider using artificial anchors like winch points or ground anchors.

- Ensure that anchors are placed at safe distances and angles to provide effective support.

Equipment and Gear Check

- Ensure that all recovery equipment, such as winches, cables, straps, and hooks, are in good working condition.

- Verify that all safety gear, including helmets, harnesses, and gloves, is available and properly maintained.

- Prepare any specialized equipment needed for the specific terrain and casualty.

Risk Assessment and Mitigation

- Conduct a thorough risk assessment to identify potential hazards and risks associated with the recovery operation.

- Develop a risk mitigation plan that includes contingency measures and escape routes in case of unexpected situations.

Casualty Assessment

- Assess the condition of the casualty to determine the appropriate method of extraction and any medical requirements.

- Coordinate with medical personnel if necessary and ensure that the casualty is stabilized before attempting recovery.

Execution and Monitoring

- Begin the recovery operation, following the planned extrication path and using anchors and equipment as required.

- Continuously monitor ground stability, obstacles, and the condition of the recovery vehicle and casualty during the operation.

- Maintain clear communication among team members and be prepared to adapt the plan if conditions change.

Debriefing and Evaluation

- After the recovery is complete, conduct a debriefing session to discuss what went well and any lessons learned.

- Document any equipment damage or issues for future maintenance.

- Review the operation and consider improvements for future operations.

By following this systematic process, you can ensure a safer and more effective recovery of a casualty from hostile terrain, minimizing risks to both the recovery team and the casualty.

RESISTANCE FACTORS TO CONSIDER

6.7. RESISTANCE FACTORS TO CONSIDER

Towing and recovery operations involve moving disabled or immobilized vehicles safely from one location to another. To ensure the success and safety of these operations, it’s crucial to consider various resistance factors that can affect the process. Resistance factors in towing and recovery can be broadly categorized into environmental factors, vehicle-related factors, and operational factors. Here’s an overview of these factors:

Environmental Factors:

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Terrain

The type of terrain on which the towing or recovery operation takes place can significantly impact the resistance. Rough and uneven terrains, such as off-road trails or mountainous areas, can create additional resistance compared to smooth, paved roads

Weather Conditions

Adverse weather conditions, such as rain, snow, ice, or mud, can increase resistance. Slippery surfaces can make it challenging to tow or recover a vehicle safely.

Obstacles

Obstacles like trees, rocks, or debris on the road can increase resistance and pose hazards during the towing or recovery process.

Water Crossings

Crossing bodies of water adds resistance, and the depth and current of the water can significantly affect the operation’s success.

Traffic

When towing or recovering vehicles on busy roads, traffic congestion can create resistance, slowing down the operation and increasing the risk of accidents.

Vehicle-Related Factors:

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Vehicle Weight

Heavier vehicles create more resistance and require more powerful towing equipment. Towing a heavy vehicle may necessitate a specialized towing truck with higher capacity.

Vehicle Damage

The condition of the disabled vehicle affects the resistance. A vehicle with extensive damage may be more challenging to tow or recover due to misaligned wheels, locked brakes, or structural damage.

Tire Condition

Flat tires or damaged wheels can increase resistance when towing or recovering a vehicle. Properly inflated and functional tires reduce resistance.

Vehicle Type

The type of vehicle being towed or recovered matters. Different types, such as motorcycles, cars, trucks, or large commercial vehicles, may require specialized equipment and techniques.

Towing and recovery operations require careful consideration of various resistance factors to ensure safety and success. Proper planning, equipment selection, operator training, and adherence to safety guidelines are essential for minimizing resistance and achieving a successful outcome in these operations.

VEHICLE WEIGHTS

6.7. VEHICLE WEIGHTS

WHERE CAN I FIND HOW MUCH THE VEHICLE WEIGHS?

- Owners Manual

- CAA Manual

- Tire Ratings x4

- Vin Tag (for weight rating)

TYPES OF RESISTANCE

FOUR TYPES OF RESISTANCE

ROLLING RESISTANCE:

The tires and wheels are rolling. Comes in 2 levels- hard surface , or soft surface.

DAMAGE RESISTANCE:

Its not going to roll. The object has no wheels.

MIRE RESISTANCE:

It’s stuck in the mud, snow, sand, or soft grass. Comes in 3 different levels.

GRADIENT RESISTANCE:

When the object is pulled up or down a grade. Gradient resistance has many different levels as it depends upon the degree of the grade.

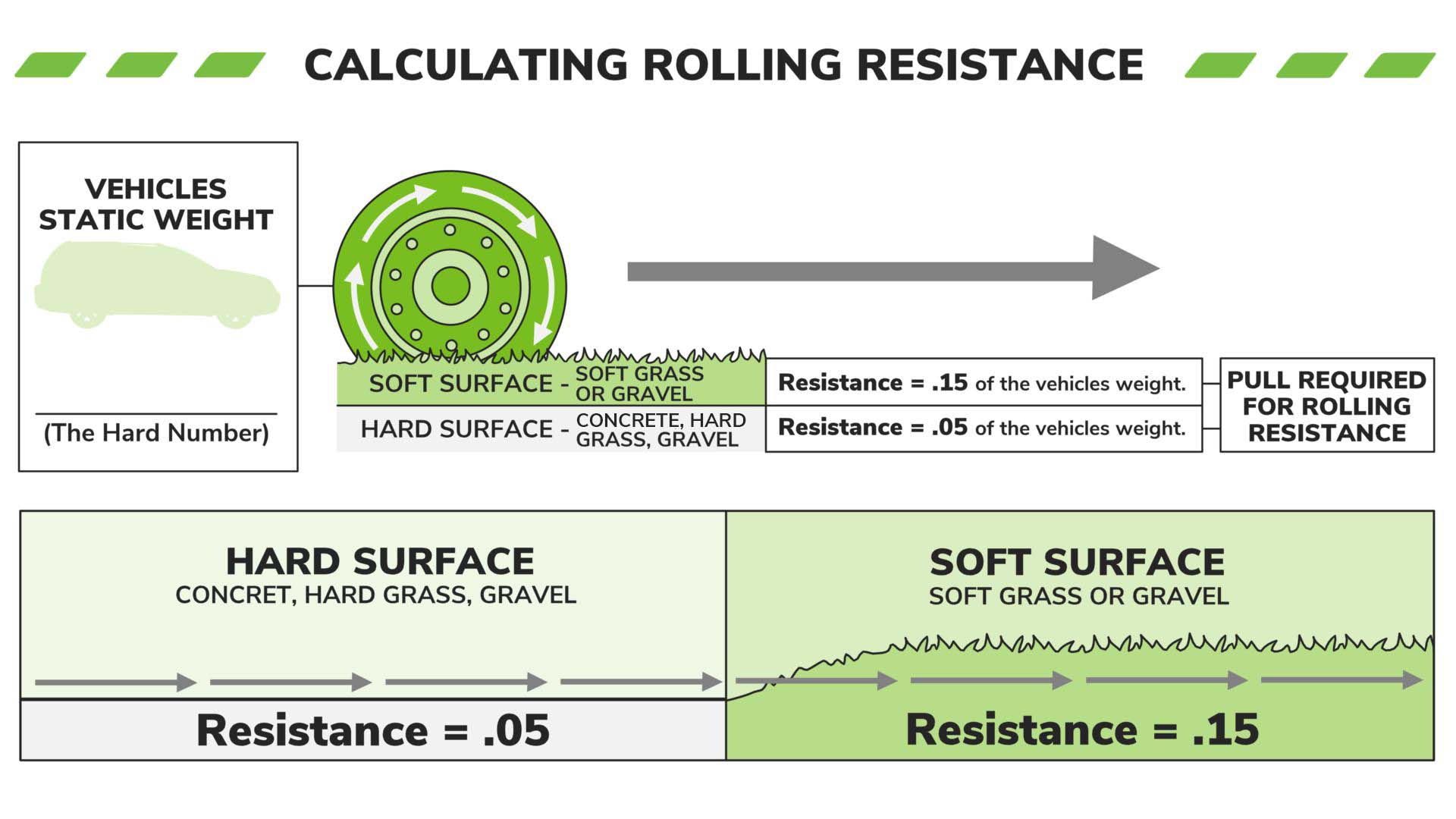

CALCULATING ROLLING RESISTANCE

6.7. CALCULATING ROLLING RESISTANCE

Rolling resistance is a crucial factor to consider when preparing to tow a vehicle because it determines the force required to move the disabled or immobilized vehicle. Calculating rolling resistance allows you to choose the appropriate towing equipment and ensure a safe and efficient towing operation. Rolling resistance depends on several factors, including the weight of the vehicle, tire condition, road surface, and environmental conditions. Here’s how to calculate rolling resistance:

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

1. Determine the Weight of the Vehicle:

The weight of the vehicle you plan to tow is a critical factor in calculating rolling resistance. You’ll need to know the total weight of the disabled vehicle, including any passengers or cargo if applicable. This weight is typically measured in pounds or kilograms.

2. Assess Tire Condition:

Rolling resistance also depends on the condition of the tires on both the towing vehicle and the disabled vehicle. Tire condition is represented by the coefficient of rolling resistance (Crr). This coefficient is a dimensionless number typically provided by tire manufacturers for specific tire types and conditions. It can vary depending on the tire’s design, tread pattern, inflation pressure, and wear. Look for the Crr value in the tire’s specifications or consult the manufacturer.

3. Identify the Road Surface:

The type of road or surface on which you plan to tow the vehicle can significantly affect rolling resistance. Different road surfaces, such as asphalt, concrete, gravel, or off-road terrain, will have varying coefficients for rolling resistance. This value is usually determined empirically or found in engineering references.

4. Account for Environmental Conditions (Windy Conditions, Inclines, etc.):

Consider any additional environmental factors that may affect rolling resistance. For example, strong headwinds or towing uphill will increase resistance, while tailwinds or towing downhill may reduce resistance. These factors are often challenging to quantify precisely but should be considered in your overall assessment.

5. Calculate Rolling Resistance Force:

To calculate rolling resistance, you can use the following formula:

Hard Surface Reistance = .05

(concrete, hard grass, gravel)

Soft Surface Resistance = .15

(soft grass or gravel)

6. Consider Additional Forces:

Keep in mind that rolling resistance is just one of the forces you need to overcome during towing. You may also need to account for other forces, such as air resistance, grade resistance (if towing on an incline), and any additional forces due to vehicle damage or obstacles.

7. Select Appropriate Towing Equipment:

Based on the calculated rolling resistance force, choose towing equipment, such as a tow truck or trailer, with sufficient capacity to overcome this force. Make sure to consider safety margins to handle unexpected variations in resistance.

Calculating rolling resistance provides a foundation for selecting the right towing equipment and planning a successful towing operation. Remember that real-world conditions can vary, so it’s essential to use conservative estimates and adapt your plan as needed during the towing process to ensure safety and success.

NOTE:

If the casualty is stuck in the mud, is on a grade, or has tire damage, these are other factors that are very important in determining the over all resistance of the casualty.

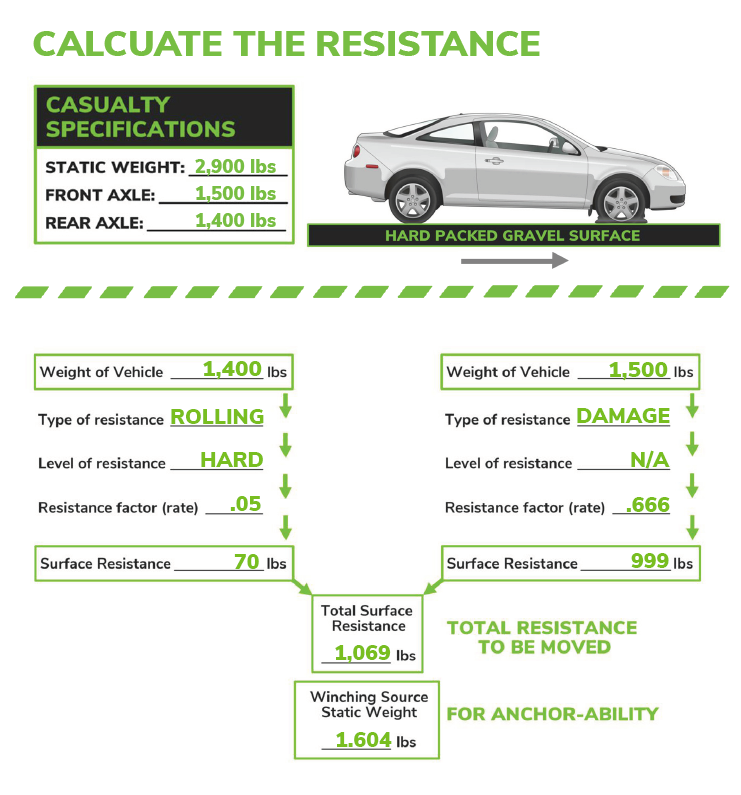

RESISTANCE CALCULATION EXAMPLE:

Below is a simple Resistance Problem demonstrating a casualty that is rolling hard with a flat tire:

SCENARIO & FACTS:

A car weighing 2,900 lbs requires service:

- Front axle weighs 1.500 lbs

- Rear axle weighs 1,400 lbs

- Both front tires are flat

- The rear axle has no damage and the tires are wheels will rotate freely.

- The tie rod is bent

- The front tires are not going to rotate when the unit moves.

- The car is on a hard packed gravel surface.

- The driver is at the scene.

- The car is almost new.

- The only mechanical damage is the front axle.

- The conditions are; clear weather, 2 p.m., one police officer on the scene and the traffic is normal.

What is the surface resistance to be overcome if a winching method is employed?