Carrier: Loading, Unloading, & Securing

- After winching the vehicle onto the carrier deck,INSTALL A FRONT TIE DOWN, IMMEDIATELY.

- Raise the edge of the deck off the ground surface by tilting slightly. This will prevent scraping the grounds surface.

- Once the edge of the deck has lifted, begin to slide the deck forward. Continue sliding the deck forward until the majority of the casualty’s weight passes the rear axel of the truck.

As shown above, the casualty’s front axle is just forward the trucks rear axle, distributing the weight over the deck rams. This will prevent the deck from ‘floating’ and putting extensive stresses on the hinge-pins and ram-mounts.

4. Once this position is reached, tilt the deck to 3°-5° above horizontal, and we are ready to install the rears.

IMPORTANT THINGS TO REMEMBER

- At NO TIME should an operator permit ANY individual to place him/her self behind the deck of any carrier until after the load has been completely and properly secured.

- The cab of a carrier or wrecker should have NO MORE occupant’s than the Manufacturer has supplied seat-belts for.

- The primary function of rotating beacons or emergency lighting is to provide a ROAD SIDE WARNING.

NOTE

PTO’S operating range RPM – Idle to 1,000 RPM’s or MANUFACTURERS SPECIFICATION.

WRECKMASTER’S MANDATORY 4 POINTS OF SECUREMENT

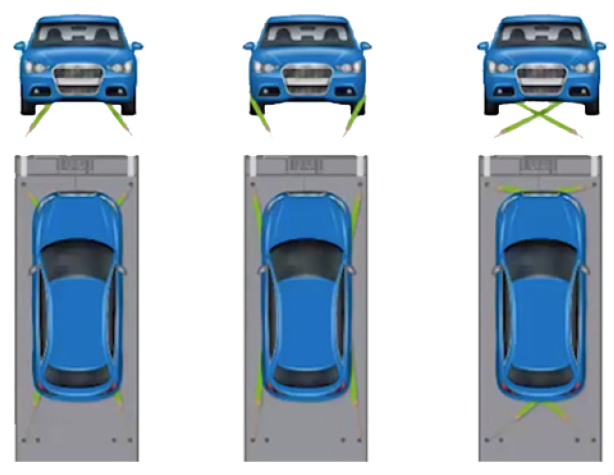

Each securement device must have a means of adjustment. The image below illustrates the Wreckmaster mandatory 4 Points of Securement, which does not rely on the use of the winch to tighten or secure the load in full compliance of the Federal Motor Carrier safety regulations.