Capacity & Height

Capacity & Height

Over-dimensional transport is a niche market that is specialized in every way. We see super loads moving along the highways, supported by hundreds of tires. Each tire is responsible for carrying a specific percentage of the load’s weight.

The heaviest super loads hauled in the United States have weighed upwards of 800,000 lbs. In comparison, hooking the steering axle of a 70,000 lbs. Concrete mixer to the under lift of a heavy-duty wrecker seems like a light duty-tow. But consider the implications of loading a heavy-duty wrecker’s drive axle suspension with that casualty in tow.

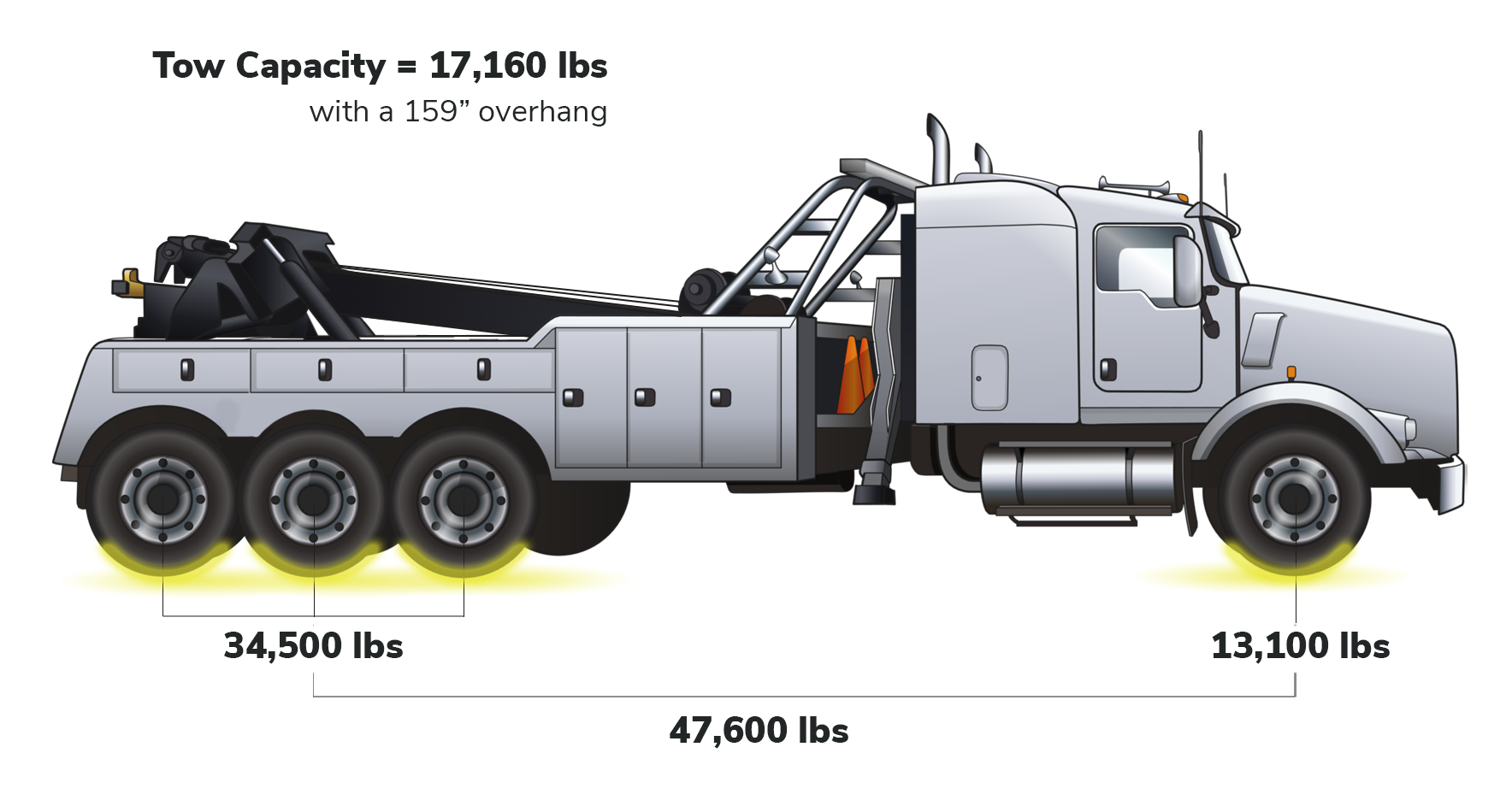

An example of a well-proportioned 50-ton wrecker has an unladen steering axle weight of 13,100 lbs. when its pusher axle is properly adjusted. The tridem carries a total of 34,500 lbs. Combined, this wrecker has a static weight of 47,600 lbs. After calculating the tow capacity of this wrecker, we find that a maximum weight of 17,160 lbs. can be placed on the underlift with 159” of overhang and still retain half of its original front axle weight.

When that lift and tow procedure has been executed, the force on the wrecker’s three rear axles is 58,210 lbs. This calculation was accomplished by knowing the wrecker’s steering axle weight, its wheelbase and the overhang distance from the rear pivot point to the center of the underlift. Knowing how to make this calculation will provide an operator with the confidence to know how much weight is left on the steering axle to properly steer and slow down the combination vehicle.

But it does reveal a truth that cannot be ignored. How much load is on the wrecker suspension? This includes its tires, wheels, axles, wheel bearings and more. I know from experience that the 58,210 lbs. that I referred to a moment ago isn’t distributed evenly across each axle.