Snatch Block Rigging

A snatch block is a simple yet incredibly versatile tool. It is used to gain a mechanical advantage, reduce line load or change the direction of a wire rope.

A few things to know about snatch blocks:

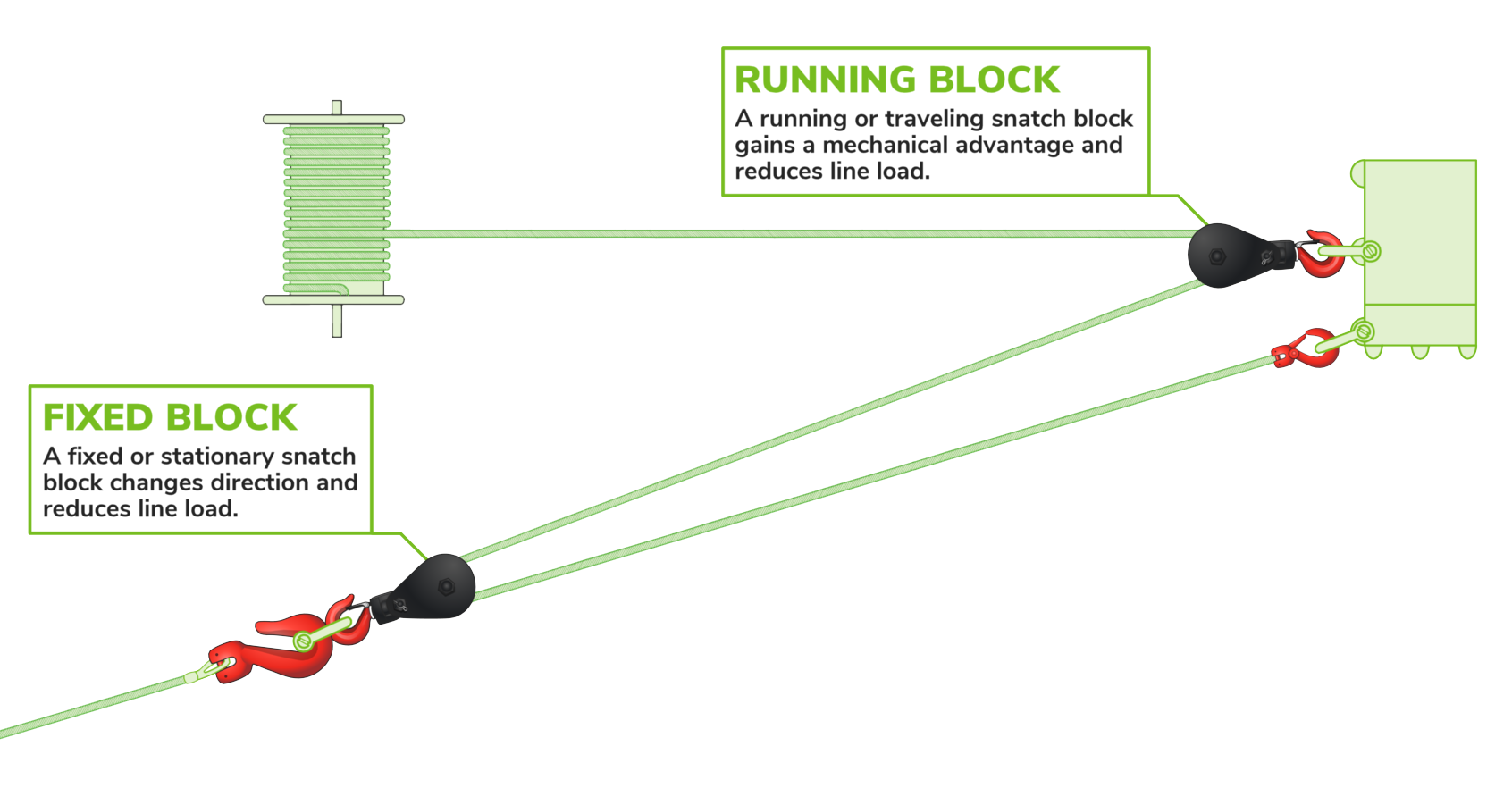

SNATCH BLOCKS WORK IN SEVERAL WAYS

TO GAIN MECHANICAL ADVANTAGE, REDUCE LINE LOAD TO CHANGE DIRECTION OF THE WIRE ROPE.

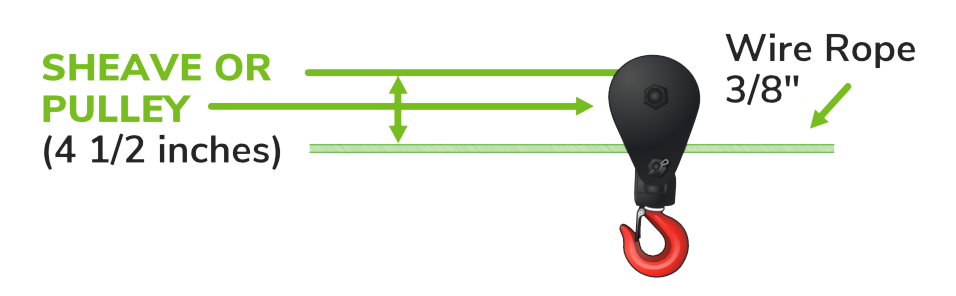

Use of proper size snatch block is important for longer wire rope life. Pulley or sheave size is important. The formula to determine the proper size sheave is based on a 12 to 1 (12:1) ratio. If you use 3/8” wire rope, then you multiply the wire rope size by 12. (3/8 x 12 = 4.56) This calculation indicates you should use a snatch block with a sheave diameter of at least 4 1/2”.

In using a pulley of a smaller size, you will damage the wire rope and shorten its life. If the angle is too sharp around the sheave, this does not give the wire rope enough distance to maintain its shape and therefore damages the strands of the wire rope.

REMEMBER

A snatch block needs to be LUBRICATED AFTER EVERY USE.

Use it, lubricate it, then put it away.

Fleet Angle is the entrance and exit angles of the wire rope relative to the sheave and should be no more than 1 1/2 to 2 degrees.

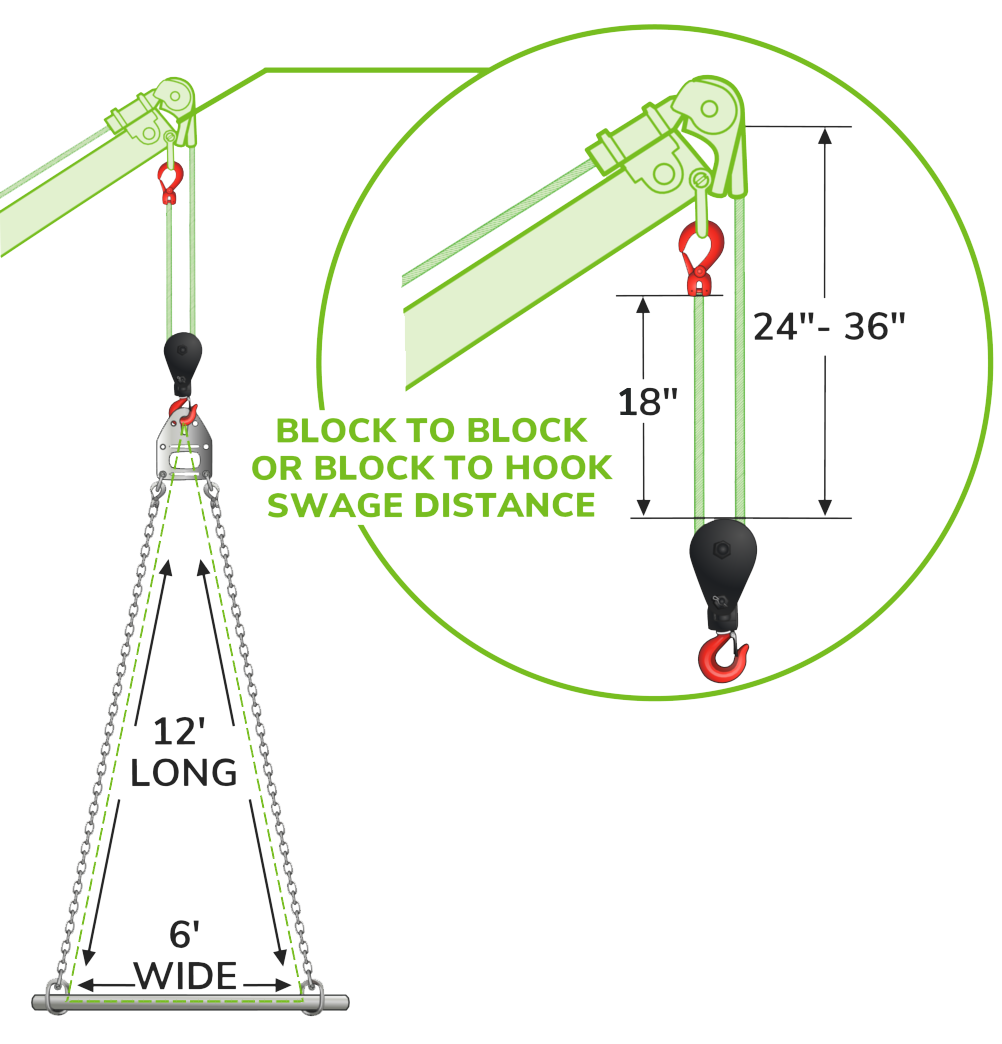

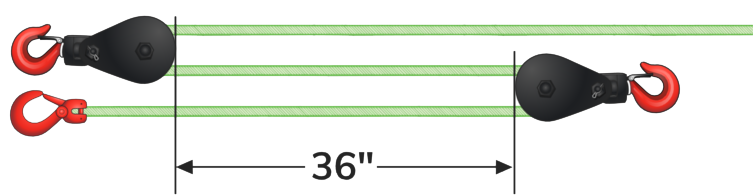

SNATCHBLOCKS CAN BE USED WITH BRIDLES

Length twice the width or 2 to 1 (2:1) ratio.

When using a bridle or sling, best practice is to maintain a 2 to 1 (2:1) ratio.

NOTE: It is not recommended to have the angle between bridle leg and load, less than 30 degrees.

REMEMBER

Manufacturers rate SNATCH BLOCKS in Metric Tonnes.

Metric Tonne is equal to 2,204 lbs.