Synthetic Winch Line Rope

ADVANTAGES OF SYNTHETIC VS. WIRE WINCH LINE ROPE

Synthetic winch lines are becoming increasingly popular as a replacement to steel rope, because they offer many advantages. Some of the advantages over traditional steel rope include:

- Easier to handle: The smooth surface has no burrs to cut your hands.

- Flexible: Even bird-nesting of the winch won’t damage synthetic rope.

- Lightweight: Easier to carry and maneuver.

- No memory: No flat spots or kinks.

- Better in water: Synthetic rope floats.

SYNTHETIC WINCH LINES

Material used varies by manufacturer. Some materials used are polyethylene, MFP Blend Polyester or par-aramid synthetic fiber.

Brand names associated with these types of synthetic fiber material are: Dyneema, Spectra and Kevlar.

Manufactures; such as Samson, Amsteel Blue ( a division of Master Pull), and Atlantic Baird for example, take these synthetic fibers to weave or braid them into synthetic ropes used in the Towing/ Recovery, Logging, Construction, Utility, Fire/Rope Rescue, Off-road/ ATV and Aerospace Industries.

PREPARATION & CONVERSION TO SYNTHETIC WINCH LINE

If installing synthetic rope on a winch that had previously used steel winch line, inspect all surfaces the steel line touched for burrs or sharp edges. This includes the winch drum, roller fair lead, tensioner, snatch blocks, side-pullers, or even sheave wheel guides. If a burr or edge is found it must be removed with a grinder or steel brush. Once cleaned, attach the synthetic winch line according to the manufacturer’s instructions.

REMEMBER

- Like steel winch line, avoid shock loading the line.

- Knots in the line will reduce its pulling capacity.

- Avoid sparks or temperatures above 158ºF that can burn or melt the line.

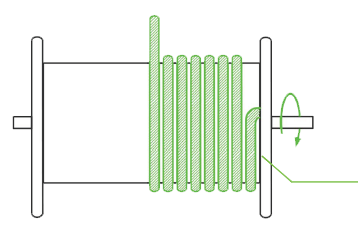

- Synthetic winch lines require a minimum of SEVEN (7) WRAPS around the winch drum to maintain its grip on the winch drum.

INSPECTING SYNTHETIC WINCH LINE

Just like steel winch line, synthetic winch lines should be inspected prior to each use. When using synthetic winch line, be on the lookout for signs of damage or wear:

REGULAR WEAR

This is typical and has a slight fuzzy look or color fading caused by abrasion. The rope can still be used: Watch closely for further, more serious signs of wear.

COMPRESSION DAMAGE

This shows as a more visible sheen and stiffness than rest of the rope. This is often caused by setting the fiber around a winch drum or hook. Can be corrected: Bend rop back and forth to remove compression.

PULL STRAND

A strand protruding from rest of rope. Can be corrected: Work the strand back in the rope by pulling back and forth.

CHEMICAL DEGRADATION

This shows as fused or bonded fibers, discoloration or brittleness. Replace this rope immediately.

HEAT DEGRADATION

Fused or melted fibers that are very stiff and can’t be loosened by bending. Replace this rope immediately.

INCONSISTANT DIAMETER

Tight flat areas that look like strand or strands have been pulled tight. These are typically caused by a broken or pulled internal strand or shock loading. Replace this rope immediately.

VOLUME REDUCTION/ CUT STRANDS

Reduced size of strands and/or rope diameter. These are broken strands caused by cuts, abrasion, sharp surfaces, or fatigue. When any strand is completely or partially cut, the entire line is compromised. Replace this rope immediately.